In this article I discuss how to fix the radiant floor heat in my basement after replacing the heat source (How To? - Hot Water Tank Replacement - Bradford White - 6 1 Error Code). The challenge is to get the manifold flow right for each loop to maximize the heating in each loop since I am using a constant flow pump. Also, upon closer examination when restarting the system, I noticed that I had to do some other repairs (new circulation pump and flow meter cleaning and O-ring replacement).

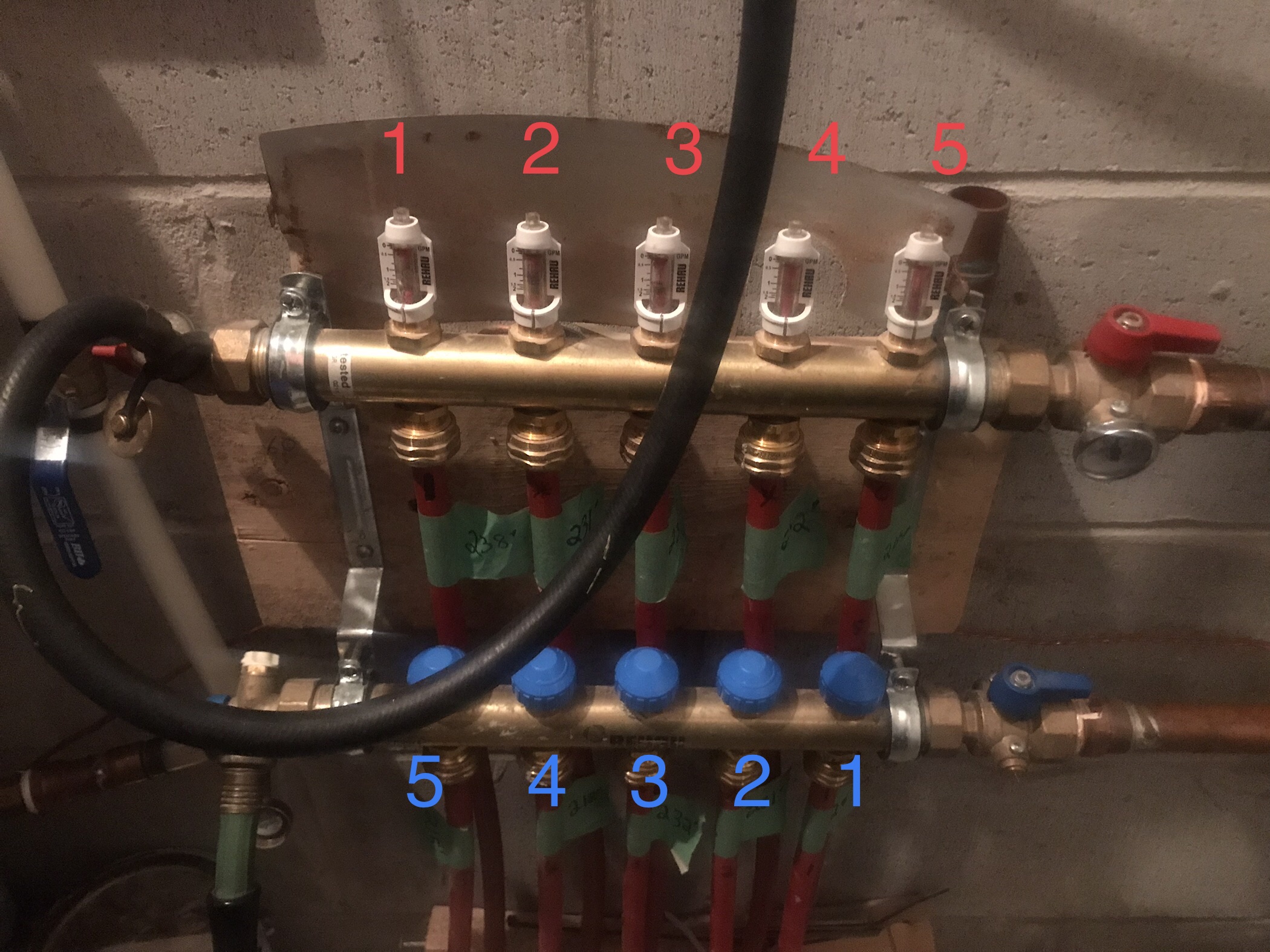

Manifold - Polypipe

My manifold is a 5 a port Polypipe Brass manifold. This manufacturer tends to be popular in the UK (not sure where I sourced it originally when I built the house?). I needed to refill and potentially recalibrate my loops to get the floor heating properly after I replaced my water heater as the repair emptied the water.

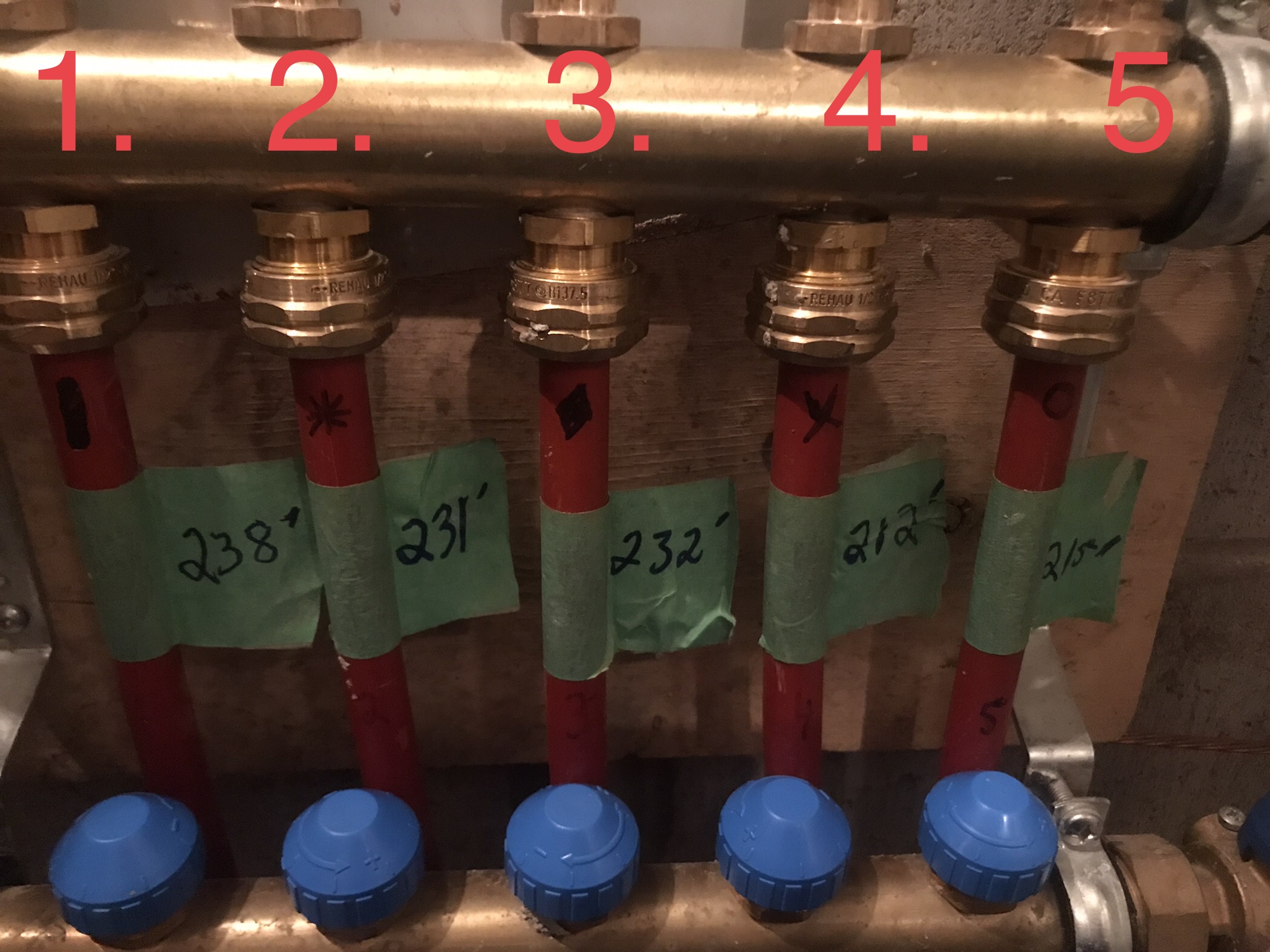

In my case I am using a 5 port manifold.

From the photo you can see that the rails on my manifold are installed backwards? Typically you see the cold water rail above the hot water rail with the flow valves below? Not sure if this matters but it ran fine for 12 years until the hot water heater needed to be replaced.

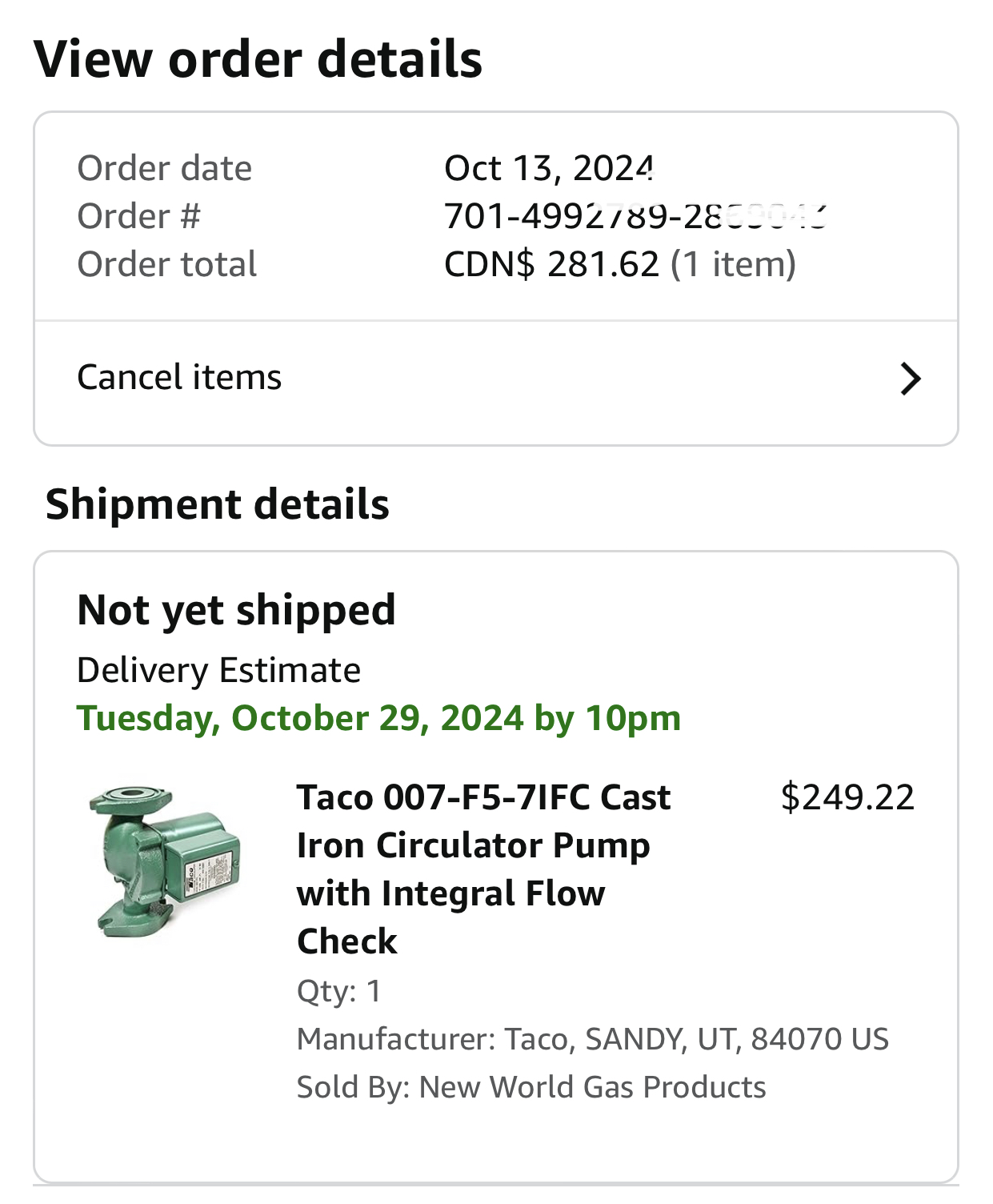

Circulation Pump - TACO

The circulating pump that I have installed is a TACO 007-F5. This pump was repurposed from the pool heating loop when I rebuilt my house (so it is more than 12 years old). In my case when I replaced the water heater, I noticed that the pump was running very, very hot - in fact it was very hot to the touch (burning). Also, my flow valve indicators were all at the top (meaning 0 kg/hr flow or no flow) when I restarted the system. I tried flushing and refilling as well as tweaking the flow on a couple loops which resulted in no change on the flow meters. Also, the system could not raise the temperature beyond ambient temperature even thou the system had 100 degree water entering from the hot water tank. So it looks like it is time to source a new replacement circulating pump.

I sourced a new “like for like” TACO replacement pump with gaskets from “New World Gas Products” via Amazon and turned off the pump controller unit until it arrives.

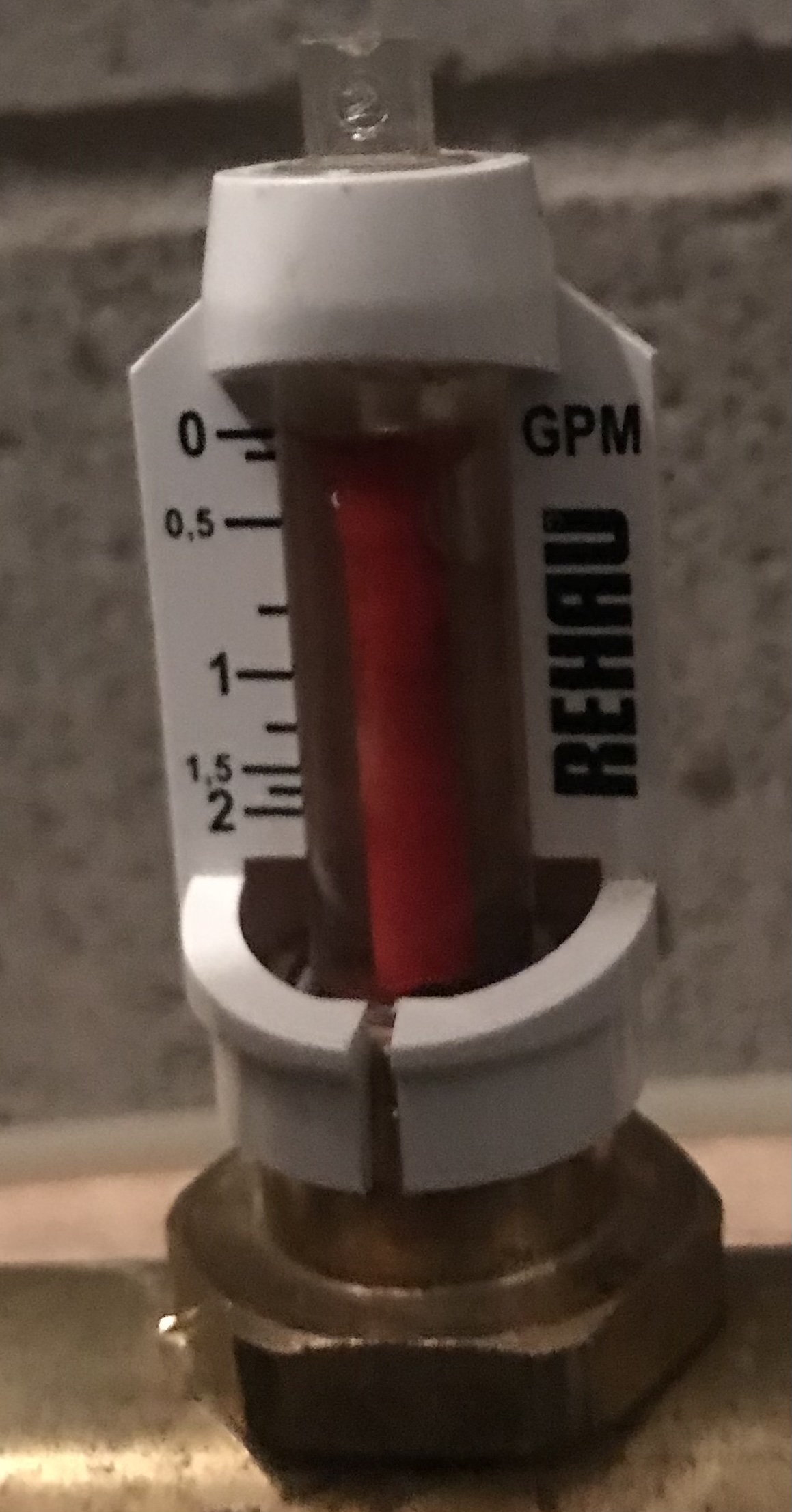

Flow Meters - Polypipe GPM

While waiting for the new TACO circulating pump I decided to inspect the flow meters. In removing them, I noticed that they were in need of cleaning as well the loop 1 flow meter needed a new O-ring. I made a rig to soak the flow meters for cleaning and replaced the bad O-ring. After cleaning the flow meters, I re-installed them. Using the filler and drain lines I was able to tune / normalize the flow rates (set them all to approximately .75 GPM - gallons per minute) for each loop until I can further tune them once the new pump is installed.

Loop Tuning

In order to properly tune the loops, I need to know the length of each loop to do the calculations for the optimal flow rate (GPM - gallons per minute). The loops are counted from left to right on the top (Hot) rail numbered 1 to 5. And on the lower rail there are in reverse order from left to right on the bottom (Cold) rail numbered 5 to 1.

When you adjust the first actuator on the bottom (Cold) rail, the flow rate meter on loop 5 on the top (Hot) rail will change.

Loop Lengths (from the top ‘Hot’ rail):

- 238’

- 231’

- 232’

- 212’

- 215’

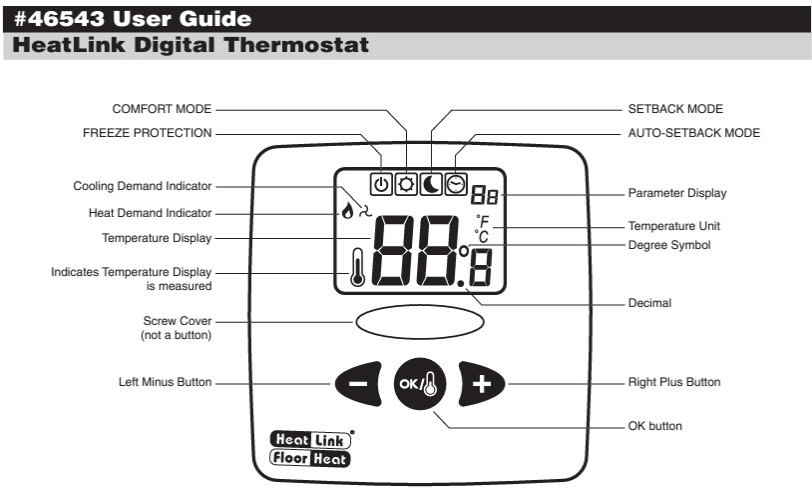

Thermostat - Heatlink

My system is controlled by a Heatlink Digital Thermostat

This controller is able to be set into multiple modes, including an anti-freeze mode. For my purposes, I just want to keep the floor warm during the winter season so I typically set it to around 72 degrees using the comfort mode. This should just maintain the floor at a constant temperature and I can then just turn off the system during the summer months.

Update - New TACO Pump Installed

I received and installed the new TACO pump, flushed the system, and have it running again. I have the valves set to approximately the same level (just above the vale seat) and I screwed down the blue caps (on the cold rail) all the way down then back them off to establish the flows for each loop. You can see from the flow valves that there are flows being monitored for each loop at a range around .75 to 1 Gallon per Minute (GPM) on each loop.

The floor warmed up from around 65 degrees (F) to the setpoint of 75 degrees (F).

Next step will be to potentially further optimize the flow (Loop Tuning) for each loop but for now I am happy with the nice warm floor.

Restarting the Floor

In order to get the system running after a prolonged time off, you likely will need to "bleed" the loops - effectively getting rid of any air in the system. Simply open the drain line while having the fill line also open.